RJ Lee Group 6 min read

Environmental Stress Cracking in Plastics

CATEGORIES

Contributors

RJ Lee Group

Subscribe to our newsletter

Environmental stress cracking (ESC) is a well-documented phenomenon in plastic/polymer components and can occur when a polymer component is exposed to an aggressive chemical agent while under tensile stress, whether residual or applied. Also referred to as environmental stress crazing, this process is analogous to stress corrosion cracking (SCC) in metals and likewise requires three ingredients for this failure mode to occur: 1) a susceptible polymer formulation; 2) sufficient tensile stress imparted on the polymer component; and 3) an aggressive environment or chemical agent in contact with the component. If any of these three conditions are not met, environmental stress cracking (ESC) will not be active1.

.jpg)

A classic example of this failure mode can be illustrated by an experiment employing a polycarbonate plate sample sitting under a bending tensile stress. The sample essentially sits indefinitely under the imposed tensile stress conditions; until a small droplet of solvent is added onto the tensile surface of the sample. At the moment of contact with the solvent, the sample spontaneously cracks and flies apart very quickly and forcefully2. The application of the solvent was the fulfillment of the third and final requirement for the ESC failure mode to present itself.

The conditions leading to this mode of failure can be elusive and many times will not be obvious, even to the trained eye. The rate and severity of material response to ESC will be dictated by the service environment and the material involved, and leak-before-break conditions can occur rather than the dramatic catastrophic fracture described above. One such instance occurred in a newly installed community water distribution system employing olefin-based polymer lines. After installation, a sanitizing agent was used to clean and disinfect the lines. The agent was not subsequently flushed and remained in the internal environment of the lines. This was not a problem in and of itself; however, contrary to installation instructions, the installation practices had created “gooseneck” curves in the lines at the entry locations to many of the residences. This geometry created tensile stressed regions on the inside surfaces of some of the lines. Figure 1 depicts one of the connections that had cracked as a result of the bend which imparted a tensile stress during installation.

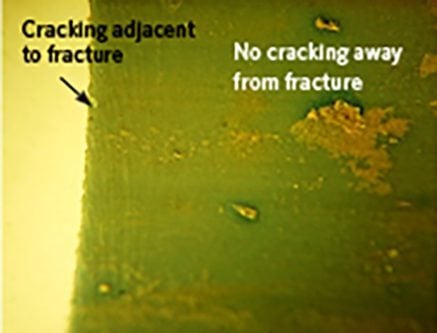

These tensile stressed locations reacted with the environment by exhibiting general degradation, strain whitening, and families of stress cracks in these bent regions, resulting in ultimate failure and leaking as shown in Figure 2.

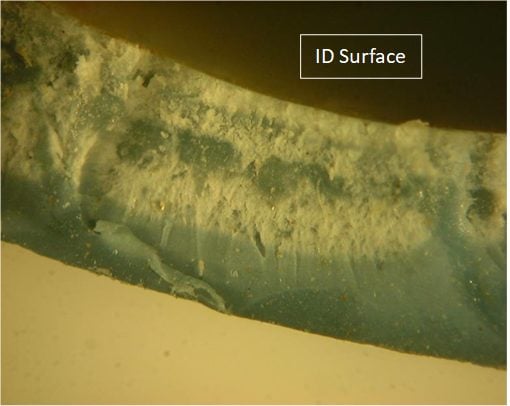

The interior diameter (ID) surfaces of the lines outside the influence of the bending tensile stress appeared relatively unaffected with no indication of alteration or problems, as observed in Figure 3.

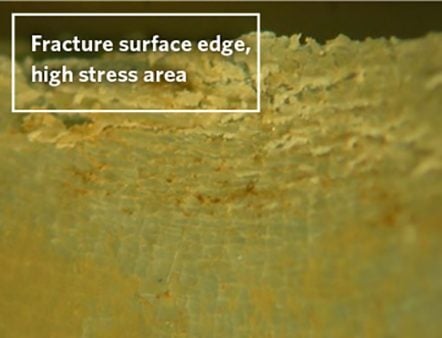

The ID surfaces of the supply lines were made susceptible to the environmental attack from a chemical agent by the presence of tensile stress. A family of stress cracks tends to form and propagate into the tube material. Typically, the stress will tend to concentrate with one crack which ultimately leads to catastrophic failure. The fracture surface of one such crack is depicted in Figure 4. This crack propagated until the strength of the remaining material became too compromised to support the load; at that moment, the component failed and began to leak.

The tensile stress is what caused the polymer to crack as exposed to the internal environment; outside the bend regions, the third ingredient (tensile stress) was not sufficiently present and therefore no cracking occurred. Figures 2 and 3 depict the most severely affected zones associated with the ID surfaces and correspond to the regions influenced by the presence of sufficient tensile stress to initiate ESC.

Unlike typical fracture behavior in crystalline materials like metals, the mechanism of ESC is generally considered to be a disentanglement of polymer chains resulting in the creation of voids or sites opened for chemical attack3. This is not necessarily associated with swelling. Like SCC, material susceptibility to specific chemicals is difficult to predict without direct testing, though surfactants that promote polymer chain sliding have been found to be ESC agents, with little correlation to their concentrations4. Some polymers’ mode of failure can be difficult to predict because the environmental composition and stress conditions can change over time; a once-benign solution can concentrate to deleterious levels through processes like evaporation and segregation, and stress conditions can change through various other mechanisms as well. Detailed knowledge of the service environment is frequently helpful in diagnosing and avoiding this failure mode.

Applicable ASTM standards include ASTM D1693-15 (ESC of Ethylene Plastics), ASTM D3929-03 (ESC by Adhesives), and ASTM F791-18 (Stress Crazing).

This summary description is offered for educational purposes only and no warranty (express or implied) is given on the applicability of this information to any particular part, material, application, or product. This article is not intended to be a complete dissertation on this topic and the reader is encouraged to contact RJ Lee Group for consultation regarding individual applications, materials, or situations.