RJ Lee Group 6 min read

Nuisance Dust Damage Claims

Contributors

RJ Lee Group

Subscribe to our newsletter

Nuisance Dust Damage Claims

A broad spectrum of industrial operations, naturally occurring sources, and vehicular emissions has the potential to generate particulate that – if not properly contained – can be cause for environmental or health concerns. A combination of engineering controls and ongoing monitoring are typically deployed to ensure compliance with limits on particulate emissions that are subject to federal, state, and local clean air regulations. Particulate (dust) producing industrial activities can be project-driven (i.e. new construction), event-driven (i.e. building collapse), or an integral component of ongoing or periodic process operations. Under some circumstances, failure to limit dust emissions can lead to significant fines from local environmental regulators and lawsuits filed by owners of neighboring properties ranging from allegations of nuisance (interference with the quiet/peaceful/pleasant use of property) up to and including property damage and health impact. Among the fundamental questions at the core of any scientific investigation assessing alleged particulate emissions are: (1) identification of Subject particulate characteristics (chemical, morphological, mineralogical, etc.) that distinguish it from existing environmental sources (2) determination of potential source(s) of the Subject particulate, (3) evaluation of the distribution of Subject particulate in the community relative to background/environmental levels of dust, (4) assessment of the potential of Subject particulate to cause damage or reduce the useful life of property on which it settles. The present article will focus on the field aspects particularly pertinent to evaluating allegations of property damage due to Subject particulate exposure.

Damaged, Discolored, or Just Dusty?

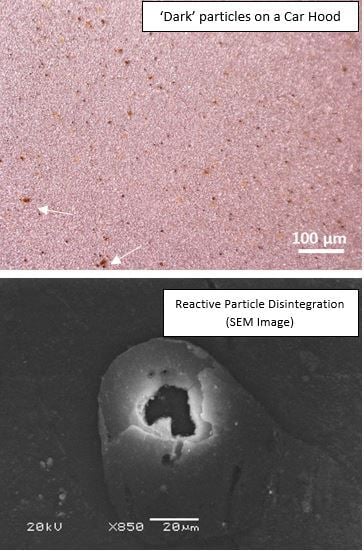

A scientific evaluation of damage claims centers on the question of whether the mere presence of particulate on a surface is evidence of damage. The answer will depend on a variety of factors, including Subject particulate adhesion to the surface, particulate weathering characteristics, and surface durability. Knowledge of material properties is necessary to evaluate modes of potential damage including aesthetic, mechanical/abrasive, and corrosive mechanisms. The visible appearances of surfaces are a common cause for complaints as event-driven observations (e.g. wind-driven plume from an industrial source or building demolition) raise concerns about observable dustiness. Carbonaceous particulate matter such as coal dust will be more visible than particulate with a lighter color appearance such as some sands; iron particulate can be reactive leading to staining or discoloration. A key technical issue becomes whether staining or discoloration is damaged if it can be cleaned. Industrial cleaning protocols exist for many types of particulate but may have limitations for some applications or environments. Evaluation of whether the useful life of an affected piece of property has been reduced is part of forensic investigations of this nature. This can only be answered through knowledge of particulate properties, surface properties, and background impacts from environmental exposures.

The stability of the particulate in the environment is key, particularly since some particles might be hygroscopic, meaning they exhibit a tendency to absorb moisture from the air:

- non-reactive particles may persist for longer periods of time, but may have difficulty adhering to surfaces and wash or blow away with time;

- reactive particles – sometimes described as deliquescent – may produce more observable effects but will disintegrate over time

Levels of active atmospheric corrosion will be much higher in coastal and in some industrial locales1, and scientific investigations must ensure to distinguish any effects of particulate exposure from this background corrosion rate. Different locations in a single property can experience conditions of varying severity due to shelter, shade, and wind direction which can impact exposure and time of wetness during periods of rain in addition to the diurnal cycles that control dewing and drying2.

Particulate Impact vs. Normal Wear and Tear

All products have a finite useful life, which is determined by the exposure conditions and the properties of the materials of construction. For widely used applications (e.g. residential housing), the life expectancy of many commonly used components has been studied3, informing building materials selection and providing critical benchmarks for insurance rates. It is natural to pay more attention to the visible condition of one’s surroundings once nuisance dust concerns arise. However, all discoloration/corrosion is not necessarily impacted by particulate exposure. Forensic scientific field assessment focuses on:

- Background levels of corrosion due to environmental exposure

- Pattern overlay of distribution of particulate and observed corrosion

- Patterns of corrosion in the absence of particulate

- Corrosion susceptibility of materials of construction

- Chemical interaction between particulate and materials

Samples of damaged materials are collected where possible for laboratory analysis. Laboratory analysis can contribute significant data in assessing the scientific validity of any damage claims. Accelerated life testing and laboratory simulations will be the subject of a future article.

This summary description is offered for educational purposes only and no warranty (express or implied) is given on the applicability of this information to any particular part, material, application, or product. This article is not intended to be a complete dissertation on this topic and the reader is encouraged to contact RJ Lee Group for consultation regarding individual applications, materials, or situations.

POTENTIALLY APPLICABLE ASTM STANDARDS

G1 – Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G46 – Standard Guide for Examination and Evaluation of Pitting Corrosion

G50 – Standard Practice for Conducting Atmospheric Corrosion Tests on Metals

G91 – Standard Practice for Monitoring Atmospheric SO2 Deposition Rate for Atmospheric Corrosivity Evaluation

G92 – Standard Practice for Characterization of Atmospheric Test Sites

1Uhlig Corrosion Handbook. Third Edition. 2011.

2 L.S. Selwyn. “Corrosion of Metal Artifacts Displayed in Outdoor Environments” ASM Handbook. Corrosion: Environments and Industries. Volume 13C. ASM International. 2006.

3 “Study of Life Expectancy of Home Components”. National Association of Homebuilders. February 2007.

Applicable Services

Field Services

Surface Lifts

Microscopy (Optical, SEM/EDS)

Analytical Chemistry

Metallography

Computer Controlled SEM