INDUSTRIES SERVED

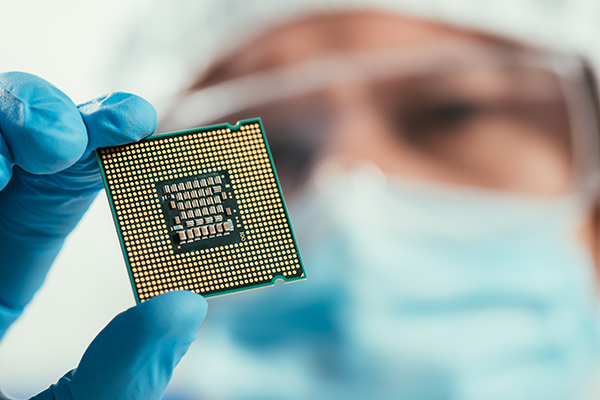

Microelectronics

Product failures hurt more than your bottom line, they can destroy your reputation and lead to costly litigation. Devices use nanomaterials with multiple metal layers deposited over hundreds of sequenced processing steps, making identifying the root cause of microelectronic failure extremely difficult. You need the most experienced and equipped partner to help you determine when and why microelectronic failure is occurring.

RJ Lee Group’s experts go beyond providing analytical data, we perform raw materials testing and analysis, analyze process-produced defects, provide analysis to augment quality assurance or quality control efforts, and evaluate the finished or returned product. We assist in interpreting your results and then successfully applying them to your manufacturing process.

Our Approach

RJ Lee Group approaches the microelectronics industry with a blend of cutting-edge technology and deep material science expertise. Our culture emphasizes precision and innovation, ensuring that our microelectronic analyses and solutions meet the highest industry standards.

Key Services

- Semiconductor Failure Analysis

- Material and Component Characterization

- Contamination Analysis and Control

- Reliability Testing and Quality Assurance

- Process Optimization and Development

What Sets Us Apart

Our standout feature in the microelectronics field is our advanced analytical capabilities, capable of addressing the industry's rapid technological advancements. Our team provides critical insights and solutions, keeping pace with the evolving demands of microelectronics.

How We Support Our Clients

Materials Service

Improve product performance with a detailed analysis of wafer substrates, residual contaminant films, point defects, and crystallographic features, including orientation and inherent stress.

Thin Film Layers and Structures

Understand the compositional and physical characteristics of deposited or grown thin film layers to better isolate and identify areas of concern or improvement.

Solder Materials

Identify defects in solder connections and evaluate the quality of lead content to improve solder connections.

Metallization Contacts, Traces, and Interconnects

Determine the location of defects and failures and evaluate whether their source is process or service-related.

IC Packages

Characterize chip failures through destructive physical analysis.

Packaging and Products

Stop odors and precipitated film residues by conducting destructive physical analysis.

Raw Materials

Ensure ROHS compliance by determining the precise concentrations of restricted substances.

Technologies

Cutting-edge Microscopic and Imaging Techniques

Advanced Semiconductor Testing and Analysis Tools

Miniaturization Technologies and Nanoelectronics

High-precision Material Characterization Equipment

Representative Clients

Semiconductor Manufacturers

Integrated Device Manufacturers

Packaging and Assembly Companies

Microelectromechanical Systems Manufacturers

Client Success Stories

Discuss Materials Analysis & Testing with an Expert