INDUSTRIES SERVED

Pharmaceuticals

A meticulous understanding of particle distribution and contamination is essential to ensuring the safety, efficacy and quality of today’s pharmaceutical products. RJ Lee Group stands at the forefront of these analyses with its ISO-compliant, FDA-registered laboratory services. Our advanced analytical capabilities and protocols are designed specifically to address the unique challenges of pharmaceutical development and manufacturing, ensuring both quality control and regulatory compliance.

RJ Lee Group’s Pharmaceutical Services Department is a cGMP compliant, ISO 17025 certified, FDA-registered analytical testing laboratory committed to applying an industrial forensics approach to Foreign Particulate Matter (FPM) investigation. Our experts use advanced materials research and quality control principles to investigate, define, isolate, and resolve problems faced within the Pharmaceutical and Biotechnology sector.

Our Approach

At RJ Lee Group, our approach to the pharmaceutical industry is deeply rooted in our commitment to advancing public health through scientific excellence. We provide comprehensive analytical services, ensuring that our pharmaceutical partners meet the highest standards of product safety, efficacy, and quality.

Key Services

- Analytical Method Development

- Quality Control and Assurance

- Regulatory Compliance Support

- Environmental Monitoring

- Product Development Consulting

What Sets Us Apart

What distinguishes RJ Lee Group in the pharmaceutical sector is our ISO-compliant, FDA-registered laboratory capabilities, combined with a relentless pursuit of innovation in analytical methodologies. Our ability to navigate the complex regulatory landscape while maintaining a focus on scientific advancement positions us as a leader in pharmaceutical analysis.

Consulting and Testing Services

Foreign Particulate Matter Analysis

Identifying and characterizing unwanted particles in pharmaceutical products to ensure patient safety and product integrity.

Contamination Identification

Utilizing state-of-the-art instrumentation to pinpoint sources of contamination that could compromise product quality.

Particle Size Analysis and Distribution

Critical for understanding the behavior of active pharmaceutical ingredients (APIs) and excipients, impacting both manufacturing processes and product performance.

How We Support Our Clients

In-Depth Particle Analysis

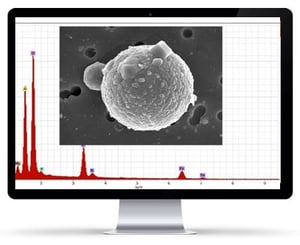

Our expert use of Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray Spectroscopy provide direct insights into particle morphology and distribution, essential to meet performance requirements.

Root Cause Analysis

Determining the origin of particulate contamination to enable corrective action.

Regulatory Support

Providing necessary laboratory analysis to navigate regulatory requirements for market approval.

Technologies

Mass Spectrometry for molecular structure determination

Clinical Data Management Systems for trial efficiency

Stability Chambers for drug shelf-life testing

Bioinformatics for innovative drug development

High-Performance Liquid Chromatography (HPLC) for compound analysis.

Mass Spectrometry for molecular structure determination

Clinical Data Management Systems for trial efficiency

Stability Chambers for drug shelf-life testing

Bioinformatics for innovative drug development

High-Performance Liquid Chromatography (HPLC) for compound analysis.

Mass Spectrometry for molecular structure determination

Clinical Data Management Systems for trial efficiency

Stability Chambers for drug shelf-life testing

Bioinformatics for innovative drug development

Representative Clients

Pharmaceutical Manufacturers

Biotechnology Firms

Research Institutions

Client Success Stories

Discuss Pharmaceutical Consulting Services with an Expert